In the process of melt blown nonwovens production line, it is easy to have broken wires and bubbles, resulting in product quality defects; the fluctuation of melt pressure is easy to cause broken flow or shutdown; when the output of melt blown nonwovens production line is high, the former melt blown screen changer is easy to stop, resulting in production interruption and serious loss. The special mesh changer for melt blown non-woven fabric provided by Zhengzhou Batte can solve the above problems well. Its advantages are as follows:

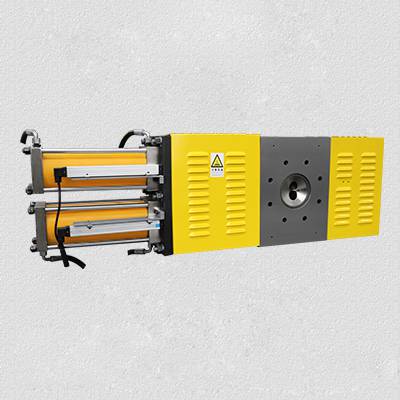

Zhengzhou Batte provides melt blown double column hydraulic screen changer, which has been supporting the main non-woven equipment in China for many years, with mature technology and stable quality; the melt blown screen changer adopts integrated design, which optimizes the equipment space and energy consumption; it can realize the operation of screen changer without shutdown; the main body of melt blown screen changer adopts special alloy material, which has undergone strict forging, surface heat treatment and precise metal addition It adopts high-quality heat treatment process and strict quality control system to ensure the stability and durability of the product; compared with the previous mesh change filter, the special mesh change filter for melt injection optimizes the structure design, realizes the function of material introduction and exhaust, and completely eliminates the fluctuation of melt pressure and temperature in the process of mesh changer.

Previous:What are the advantages of melt pump for melt blown fabricNext:Solution for leakage of volume metering pump