The recycling of agricultural and packaging films is a difficult task. Because agricultural films usually have extremely high levels of mineral and organic impu

learn more >

The recycling of agricultural and packaging films is a difficult task. Because agricultural films usually have extremely high levels of mineral and organic impu

learn more >

PET bottles are one of the most widely used plastics in our daily life, and PET bottle recycling granulation is one of the current recycling methods, after year

learn more >

Waste plastics mainly include trimmings from factories and post-consumer plastics from garbage, where trimmings from factories go directly to plastic recycling

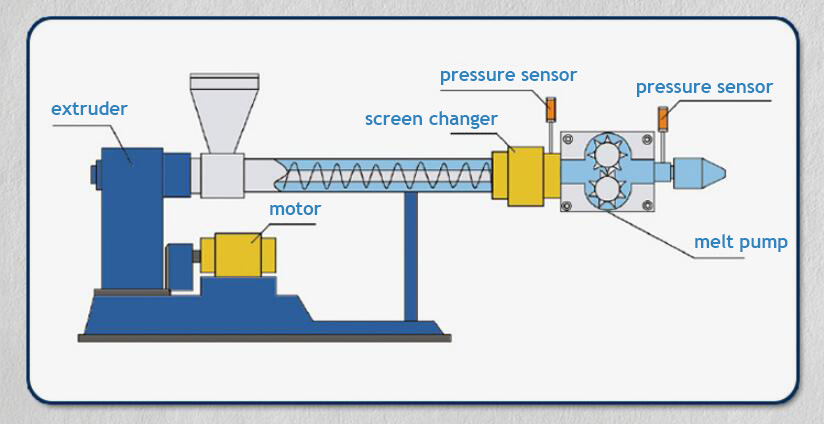

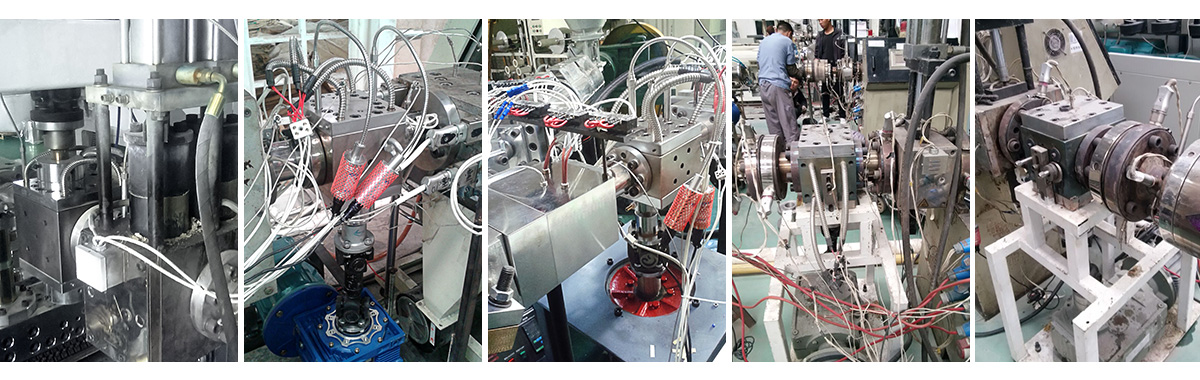

learn more >The simplest ways to make the best of extrusion melt pump function installing into extruders, Melt pumps is known as an accurate metering device that build pressure more effectively than a screw and provide more consistent pressure and volume of output than a screw, eliminates surging of the extruder screw. The extruder fills the gears from the suction side and the rotating gears discharge the polymer on the other side. it is to keep the flow and pressure of the plastic melt flow to the die at a continuous and constant level, reduces back pressure and increases output of the complete line (up to 20%). The quality of the extruded material is thus highly increased. It is used in a wide range of applications from PET sheet and rubber extrusion to recycling and compounding.

1, improve the quality of the final products

2,greatly improve the plasticizing of the raw material

3, make the product structure more homogeneous and product surface smoothness

4, protect the down stream equipments, such as Batte melt pumps and the extrusion dies

1, to improve the stability of the product size

2,melting quality control

3, increase output

4, reduce the raw materil consumption

5, improve the flexible of the extruder

6, protect the extrusion die ,extend the service life of the extruder

1, improve the melt plasticaction

2, improve the quality of the products

3, extend the service life of the extruder

4, greatly increase the output of the products

5, reduce the labor interference

6, reduce the unqualified products

1, we should operate the screen changer and melt gear pump as the safety manual, prevent an electrical shock

2, To prevent ourself scald

3, do not disassemble the screen changer and the melt gear pump, any questions, please contact with the supplier.

Polymer Melt

film, pipe, plate, sheet, granulation

High Temperature or High Viscosity Materials

PC, PMMA, ABS, HIPS, PET, PVB, PS, PP, PA, PE, PVA PET,etc.

Chemical Fiber Melt

polyester for cotton-fiber, polypropylene

Other Polymer Melt Materials

rubber, asphalt, paint, adhesives, coatings, lubricants.